I am a big fan of a newsletter called Blockworks Daily, which starts every edition with a quote that relates to the theme of the day. I like this style so much that I’ve decided to do the same here and justify it as “imitation is the sincerest form of flattery”.

“But I’m near the end and I just ain’t got the time;

And I’m wasted and I can’t find my way home.”Blind Faith, Can’t Find My Way Home

The lyrics above are clearly an artist’s rendering of transportation waste. They were likely written as a poetic metaphor for the hasty scramble to get products on the truck for delivery... only to realize later that the shipment was wasted when the customer calls to say that the right products did not find their way home.

Amirite?

[Author’s note: The lyrics could also conceivably be about a guy who is so high he doesn’t know what is up, but I’m inclined to think that 1960’s rock bands were more likely to have Lean Manufacturing principles in mind when they wrote classic songs.]

8 Sources of waste according to Lean Manufacturing principles

Either way, you might be asking:

Why is transportation viewed as waste in Lean Manufacturing?

According to Lean principles, any activity that does not add value to the customer is considered waste (or, in Lean parlance, muda). While this seems a bit paradoxical because transporting the product certainly allows the customer to experience the value, when you get down to it, transportation doesn’t add value.

The notion of transportation is quite broad, which results in a lot more waste than you might think.

It includes the obvious:

- Moving the product from station to station as part of the production process;

- Moving the product in the yard to make room for others;

- Driving a forklift around the yard looking for the right product to ship;

- Transporting materials in for manufacturing;

- Moving materials from the loading dock to another part of the plant;

- Shipping product; and, of course

- Shipping mistakes.

And, it includes the not-so-obvious:

- Walking shop tickets around the plant;

- Walking into the office to get the bill of lading for shipments;

- Sharing information by email instead of using a central information hub; and even

- Depositing checks at the bank instead of using mobile deposit.

This is what I love about Lean. One wouldn’t normally consider swapping emails or running to the bank as a big deal; but, with other more efficient alternatives available, they can... and should... be replaced.

When you consider transportation through the lens of Lean principles, it quickly becomes clear how routine, business-as-usual activities create a lot of waste!

So, how can transportation waste be contained?

Some solutions are achieved through planning and others are achieved by adopting new tools.

For the larger, more obvious sources of transportation waste, precast managers might consider:

- Hiring a Continuous Improvement manager to analyze operations and make recommendations for improvement (it will pay for itself many times over);

- Precisely matching materials availability to production scheduling in order to transfer only the correct amount of materials;

- Engaging just-in-time production scheduling to minimize product deliveries;

- Conducting a floor plan redesign that minimizes movement of product and people during manufacturing.

For those of you who might want to learn more about Lean thinking before hiring an expert, consider joining the Lean Enterprise Institute or the Lean Construction Institute. There is also a very good book called Lean Thinking which was co-written by the founder of the Lean Enterprise Institute, James Womack.

As I mentioned earlier, technology tools exist to minimize waste as well. This is the central premise of our Idencia system for precast manufacturers. Our system addresses transportation waste with:

- A portal where users can find all information about everything going on in the plant from their browser (instead of walking around asking or emailing and waiting);

- A notification system that automatically sends reminders to users (reducing email and face-to-face communications);

- Integration with Forney, LP’s ForneyVault, which electronically directs compression testing results into the user’s Idencia account (saving a trip back into the office to record results);

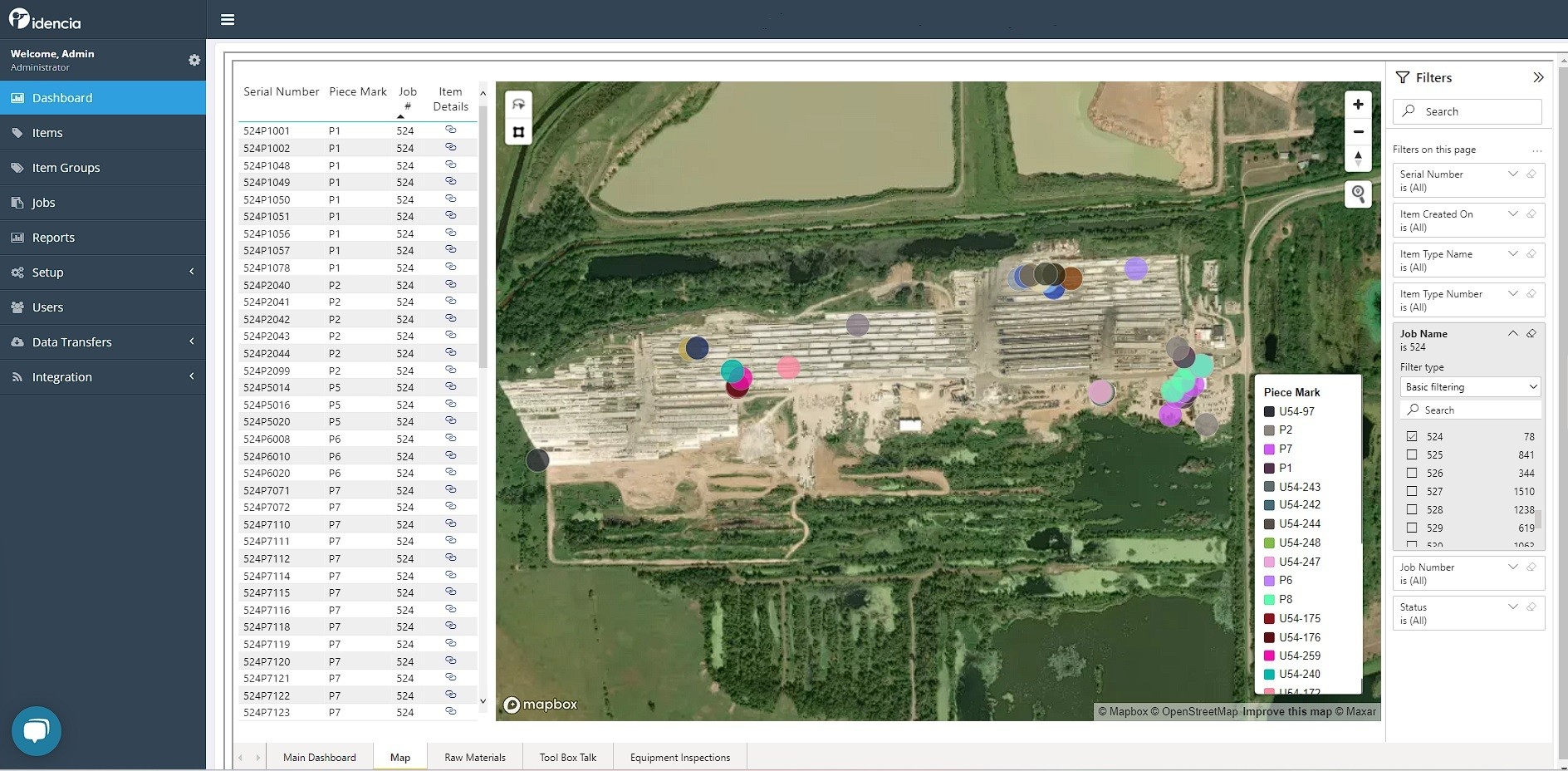

- A GPS map to quickly locate pieces in the yard (saving time traveling the yard in the forklift looking for product);

- A Shipping Module that allows users to identify the correct pieces to be loaded on the truck (eliminating the most egregious transportation waste, shipping mistakes).

GPS map of a precast yard used to search for product in Idencia

Our Shipping Module is a new addition to our solution—and we are very excited about it. Users set up shipments in their web-hosted Idencia account (which we call the Management Portal). Once the shipment is created, the data syncs with handheld devices used by people in the yard. Before loading the truck, they scan each piece and the system tells them whether or not that is the correct piece to be loaded.

Many precasters have reported that shipping errors are more prevalent than they ought to be because so many custom pieces look alike. We are happy to solve this problem and eliminate this source of transportation waste!

Next up, Non-utilized Talent as a source of waste

I’m looking forward to this one. It’s no secret that the labor shortage is a universal challenge to precast concrete manufacturers. Tapping the potential talent of current employees is a natural first step before looking outside to hire. It also presents professional growth opportunities that compel employees to want to stay—even better!

More to come on this.

This blog is part of a LinkedIn Newsletter series by Jeff Pollock, CEO of Idencia. To get the latest of what he’s writing, be sure to subscribe to his newsletter Connected Concrete.

Sep 21, 2023 11:07:33 AM

Comments