There is a popular meme circulating in social media where a CFO asks the CEO of a company: “Have you considered the cost to the company if we invest in improving the skills of our employees and they leave?” To which the CEO replies: “Have you considered the cost if we don't and they stay?” The same logic applies to investing in technology. Our conversations with GMs of precast manufacturing companies reveal that they have a strong intuitive sense that investing in technology will save money... but they are often surprised by how much.

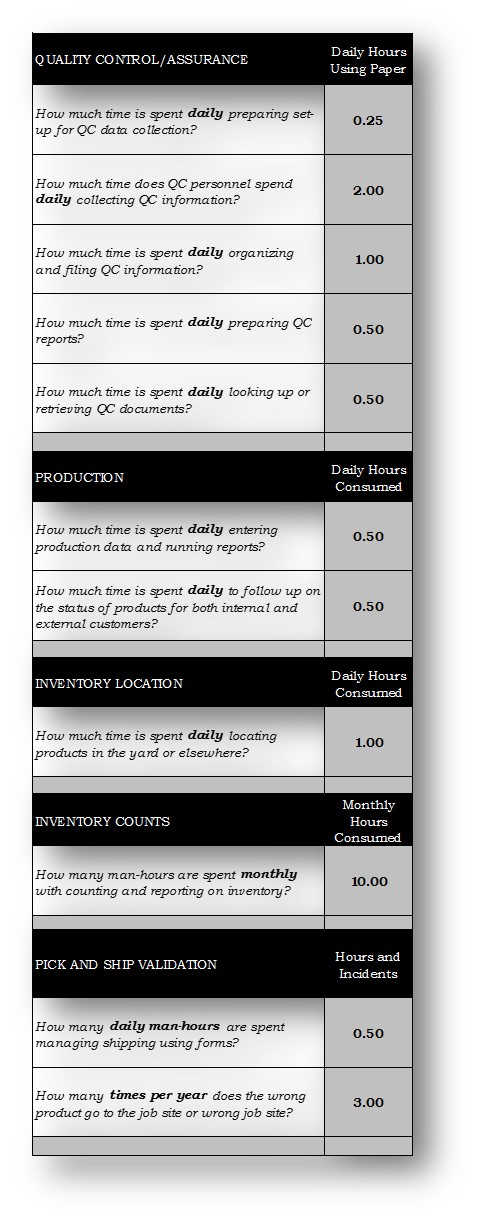

When we engage with prospects considering precast RFID tracking or bar code tracking for concrete, we offer our return-on-investment calculator to assess the cost of time spent in the following phases of operations using paper to create their records:

- Quality Control/Assurance

- Production

- Inventory Control

- Shipping

The example included here provides a representative illustration of time invested in each phase. The time doesn't look startling in any given step but it adds up. Each consumes the following number of hours in a month (assuming 22 work days):

| Quality Control | 94 |

| Production | 22 |

| Inventory Control | 32 |

| Shipping | 11 |

And, three shipping mistakes per year at an average cost of $2,500 per mistake costs an additional $7,500 per year.

Apply an average cost of $15.00 per hour for the people doing this work and the cost of using paper is:

$36,000 per year

Much of this time can be eliminated by using tablet technology to enter information once. The information is filed without additional work and the necessary reports are automatically generated on demand. Moreover, the cost of paper and space for files (not included in this analysis) is virtually eliminated.

This is just one example of one application of technology. So, the question every precast manager needs to ask is:

“Can we afford NOT to invest in technology for precast?”

About Idencia

Our purpose at Idencia is to offer asset tracking solutions that improve productivity throughout the construction value chain. Our subscription offering applies RFID and bar code tracking to construction products from the time of manufacture through end-of-life. As a cloud-hosted product tracking system that is seamless between manufacturers, contractors and asset managers, Idencia adds information value to all, eliminates redundancy and saves time.

Tags:

Market Insights

Dec 10, 2016 4:02:12 PM

Comments