We serve the concrete industry with solutions for optimizing plant performance. I’ve heard a lot of stories and have acquired a good amount of wisdom from working with precast plant owners, GMs, plant managers and QC managers over the years. Happy to share what I have learned here.

Why Lean into Lean?

Personally, I am a big believer in the tenets of Lean Manufacturing principles, so I thought a series to encourage managers to “lean into” Lean Manufacturing would be a good place to start.

It is not surprising that industry leaders are moving in this direction too. Companies such as Jensen Precast and Smith-Midland Corporation have embraced lean practices, as have some suppliers like Concrete Sealants, Inc.

At their core, Lean principles are about arranging operations to maximize value for the customer and eliminate (or at least minimize) waste. Simply stated, waste is defined as anything that does not add customer value.

Since the breadth of Lean Manufacturing principles is too much to convey adequately in one article, today I will introduce the eight sources of waste and delve into the most prevalent (waiting). The others will be addressed in subsequent articles.

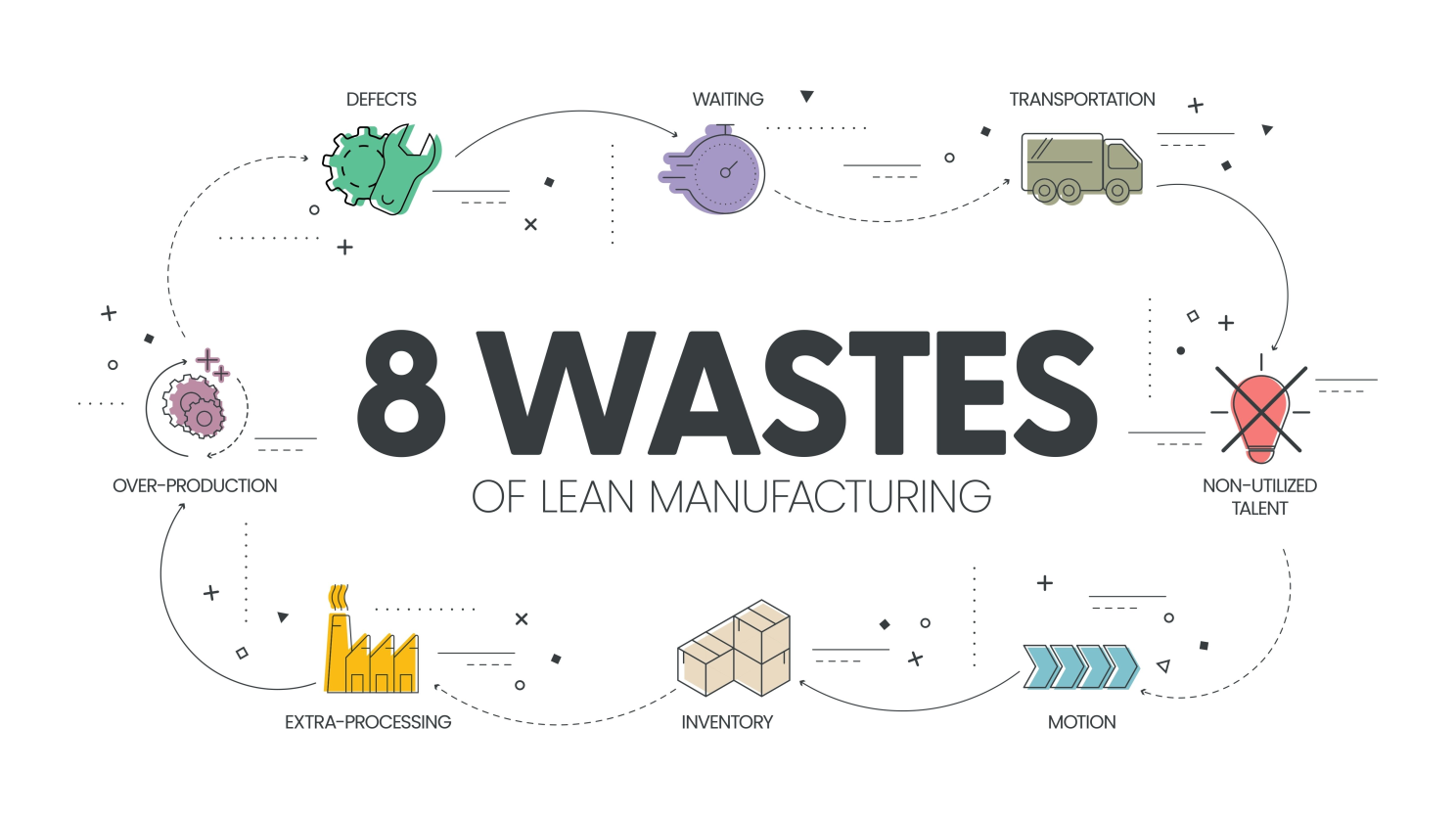

8 Sources of waste according to Lean Manufacturing principles

The 8 sources of waste

The eight sources of waste as identified in Lean Manufacturing principles can be categorized as:

- Waiting

- Transportation

- Non-utilized talent

- Motion

- Inventory

- Extra-processing

- Over-production

- Defects

Waiting is the worst... or at least it feels that way

Waiting is the waste that is most universally experienced in any plant and is typically the most frustrating:

- Production is held up at station number 2 because of a through-put problem at station number 1, thereby delaying work at all subsequent stations.

- The plant manager wants to respond to a customer status request and has to walk the plant to find the answer.

- Trucks are sitting at the gate waiting to be loaded while the forklift driver cruises the yard looking for the right piece.

- A shipment is ready to go... except for the piece that was noted as defective and never repaired before shipment time.

- Your plant auditor asks for certain QC records and you find yourself digging through files while the auditor drums his fingers on the table.

Do these sound familiar? We hear stories like this all the time. The reason waiting is the worst is because it rarely affects just one person. Rather, waiting creates a chain reaction of delays affecting others as they perform their jobs. And, since time is our most precious resource, lost time is lost money and opportunity.

Waiting creates a chain reaction of delays affecting others as they perform their jobs.

A few years ago, we created our Cost of Not Going Digital calculator to quantify the amount of time that can be saved by moving from paper record-keeping to a digital system. Many of the ‘waiting’ scenarios described above are resolved this way, so we thought it would be good to see exactly how much waiting could be reduced.

Based on the responses we have received, we can tell that the precast industry reduces wasted time by almost 2,000 man-hours per plant each year by going digital. That is equivalent to one man-year! Put another way, wasted time from conducting business as usual requires at least one more laborer than would otherwise be required. Given the current labor shortage, this is good to know.

I encourage you to take 10 minutes and answer the 15 questions in the calculator to see how much time your plant can save.

Next up, Transportation

Transportation is considered to be waste according to Lean principles because it does not add any product value to the customer. Since certain minimum transportation costs are a given, next week I’ll explore how they can be contained by avoiding simple mistakes... like delivering the wrong piece to the job site.

Some final thoughts

In parting, I would like to elaborate on a point I made in passing earlier. Idencia is not just another software system for managing a precast plant. We offer a comprehensive solution (including software and our people) to help precast manufacturers optimize plant performance.

As such, we work in conjunction with other precast software systems. (In fact, we are partnering with Concrete Vision; more on that to come.) So, if you want to learn how we can work together to help your plant continue to improve, I hope you will message me.

Thanks for reading. If you have thoughts to add, please share them. All are welcome and we would love this to start a conversation.

This blog is part of a LinkedIn Newsletter series by Jeff Pollock, CEO of Idencia. To get the latest of what he’s writing, be sure to subscribe to his newsletter Connected Concrete.

Sep 6, 2023 7:45:00 AM

Comments