In an age of global competition and compressed margins many industries are embracing lean manufacturing practices, a system designed by Toyota fifty years ago when it faced the challenge of entering a global automobile market with severely constrained resources.Participants in the construction value chain... manufacturers, contractors and asset owner/managers... are currently experiencing similar stress from a combination of huge demand and limited spending dollars. The best construction companies operate according to a set of five fundamental processes that separate the ordinary from the excellent.

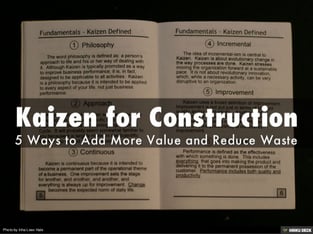

In an age of global competition and compressed margins many industries are embracing lean manufacturing practices, a system designed by Toyota fifty years ago when it faced the challenge of entering a global automobile market with severely constrained resources.Participants in the construction value chain... manufacturers, contractors and asset owner/managers... are currently experiencing similar stress from a combination of huge demand and limited spending dollars. The best construction companies operate according to a set of five fundamental processes that separate the ordinary from the excellent. Lean practices... called "Kaizen" by Toyota, a Japanese term that roughly translates to "way of being"... are all about two primary objectives:

1. Focusing on activities that add customer value; and

2. Eliminating waste (activities that don't add customer value are considered waste)

So, lean practices are about viewing your operation from the customer's perspective and dedicating resouces accordingly. They call as much for investment in value-added activties as cost cutting, notwithstanding the implication of the name.

As our Kaizen for Construction presentation outlines, companies engaged in lean construction practices will:

- Map the value stream (identify where they do and don't create customer value)

- Measure (every process for baselines and progress improvement)

- Eliminate waste (identify and eliminate non-value creating steps)

- Coordinate flow (create equilibrium between production and customer demand)

- Continuously improve (engage Kaizen as a culture)

In an article called Manage What You Can't See for Supply & Demand Chain Executive, lean manufacturing consultant, Rich Becks, points out that the most effective lean practices blur lines between supplier and customer:

"Today, successful companies are reaching beyond their four walls of the enterprise and are integrating cloud-based business network technologies to create value chains that serve customers better while lowering costs and reducing complexity. "

This is exactly what Idencia offers to the infrastructure construction value chain. As a cloud-based service that enables seamless product tracking from the time of manufacture through end-of-life, it enables supply chain cooperation that means reduced costs for all involved and greater value produced. We like to say that Idencia will create lean infrastructure.

As we wrote in Construction Product Tracking is Here (and free!), manufacturers and contractors can start using Idencia at no subscription cost. If you would like ot learn how your company can use Idencia to create more customer value and reduce operating costs, download our Idencia Primer ebook.

Jun 27, 2015 2:22:16 PM

Comments